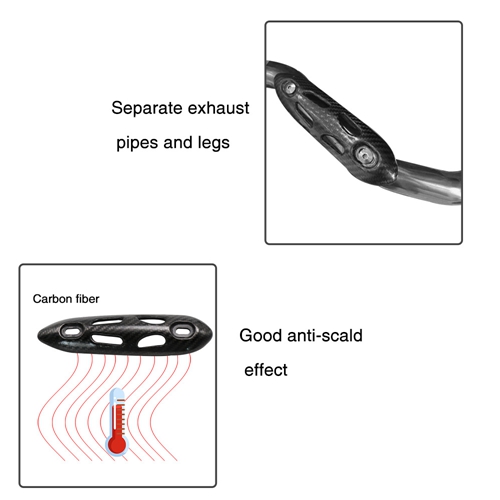

Exhaust Pipe Protector is a protective device designed for automobiles, motorcycles and industrial equipment. It effectively reduces the risk of exhaust pipe damage caused by high temperature, collision or chemical corrosion through physical isolation, heat energy dispersion and structural strengthening technology. Its core functions include thermal insulation protection, impact resistance, corrosion resistance and structural reinforcement, and it is suitable for a variety of complex working conditions.

High-efficiency thermal insulation layer

Adopting high-temperature resistant ceramic fiber composite materials, it can withstand continuous high temperatures above 600℃, effectively reducing the transfer of heat to surrounding parts (such as bumpers and car bodies), and avoiding material aging or deformation caused by thermal radiation.

The thermal insulation efficiency is 40% higher than that of traditional materials, significantly reducing the risk of damage to surrounding parts caused by high temperature.

Impact-resistant structure

The outer layer is covered with high-strength aluminum alloy or stainless steel guard plates, and honeycomb reinforcement ribs are formed through stamping and forming process, and the impact strength is increased by 300%.

Built-in elastic buffer layer (such as EPDM rubber) can absorb more than 30% of the impact energy to prevent the exhaust pipe from being broken due to scratches or stone impact.

Anti-corrosion coating

The surface is sprayed with nano-ceramic coating, and the acid and alkali corrosion resistance meets ISO 12944-6 C5-M standard. It can resist the erosion of corrosive media such as sulfur-containing exhaust gas and snow melting agent, and the service life is extended by 2-3 times.

Modular design

Adopting a split structure, there is no need to cut the original car parts for installation, and the adaptability covers more than 90% of mainstream models.

The sensor interface is reserved, compatible with the OBD-II diagnostic system, and does not affect the vehicle's annual inspection and emission monitoring.

Material selection

Thermal insulation layer: aerogel composite material is used, with thermal conductivity ≤0.02W/(m·K) and density only 1/3 of traditional materials.

Impact-resistant layer: 6061-T6 aluminum alloy is used, with yield strength ≥275MPa, and surface hardness is improved by anodizing.

Manufacturing process

Stamping: The outer guard plate is formed in one step by a 3,000-ton hydraulic press to ensure structural strength.

Hot pressing composite: The thermal insulation layer and the impact-resistant layer are bonded by high temperature and high pressure (180℃/10MPa) to avoid delamination and shedding.

Surface treatment

Nano coating: Plasma spraying technology is used, with a coating thickness of 30-50μm and a surface hardness of 9H (pencil hardness).

Automotive aftermarket

Modified cars and off-road vehicles: protect the exhaust pipe from flying rocks in off-road conditions and reduce maintenance costs.

High-performance sports cars: reduce the interference of exhaust heat on the chassis and surrounding electronic components, and improve handling stability.

Motorcycle competition

Track racing: prevent tire softening or body plastic parts melting due to exhaust pipe overheating, and improve safety.

Long-distance rally: resist the erosion of dust and gravel on the exhaust pipe and extend the service life.

Industrial equipment

Engineering machinery: protect the exhaust pipes of equipment such as generator sets and air compressors to avoid fires or equipment failures caused by high temperature.

Ship power system: isolate seawater corrosion and high-temperature exhaust gas from damaging the hull structure, and reduce maintenance frequency.

Special vehicles

Military vehicles: prevent the exhaust pipe from brittle cracking due to high or low temperatures in extreme environments such as deserts and polar regions.

Fire trucks: reduce the thermal radiation effect of high-temperature exhaust gas on the vehicle body and rescue equipment.

New energy field

Hydrogen fuel cell vehicles: protect the hydrogen emission system to prevent the risk of hydrogen leakage caused by high-temperature exhaust gas.

Extended-range electric vehicles: Isolate the thermal interference of high-temperature exhaust gas from the internal combustion engine on the battery pack and improve battery life.

Daily Inspection

Check whether the fixing bolts of the guard plate are loose and whether the coating is cracked or peeling every month.

Avoid using a high-pressure water gun to directly rinse when cleaning to prevent damage to the coating.

Seasonal Maintenance

In winter: Check the integrity of the antifreeze coating to prevent corrosion by snow melting agents.

In summer: Ensure that there is no dust accumulation on the insulation layer to avoid affecting the heat dissipation efficiency.

Professional Maintenance

Replace the anti-corrosion coating every 2 years, or shorten the cycle according to the use environment.

Perform vibration tests regularly to ensure that the guard plate is firmly connected to the exhaust pipe.

Q: Does it affect the vehicle's power performance?

A: No. The product weight is ≤2kg, and the drag coefficient is optimized to 0.03, which has no significant impact on vehicle performance.

Q: Do I need to file after installation?

A: No, but you need to ensure that the installation does not block the license plate or affect the vehicle's lights.

Q: Can it be adapted to a modified exhaust system?

A: Support customized design, suitable for modified exhaust with different diameters and bend angles.

Q: How long is the warranty period?

A: Provide 5 years/100,000 kilometers warranty, free replacement if the coating falls off or the structure is damaged.

Q: Is it suitable for diesel vehicles?

A: Fully compatible, the insulation layer can withstand the high temperature and particle erosion of diesel engine exhaust.

———————————————————————————————————————————————————————————————

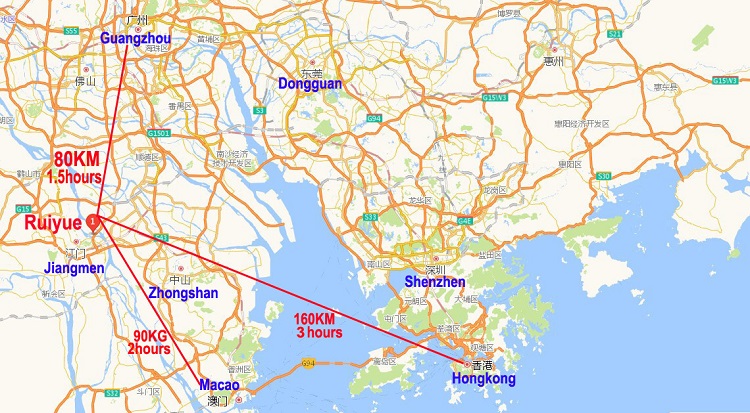

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information