Motorcycle Muffler Cover is a metal or composite shell installed at the tail of the motorcycle exhaust pipe. Its main function is to provide protection for the exhaust pipe to prevent it from physical damage, high temperature burning and external corrosion, while improving the overall appearance and safety of the vehicle. In actual use, the motorcycle exhaust pipe is easily hit by flying stones under complex road conditions, and is also prone to corrosion when exposed to moisture and salt spray for a long time. There is a risk of burns or fire when running at high temperatures. The motorcycle exhaust pipe cover can effectively solve these problems through its unique design and the selection of high-quality materials, providing all-round protection for the motorcycle exhaust pipe and bringing users a safer and more durable riding experience.

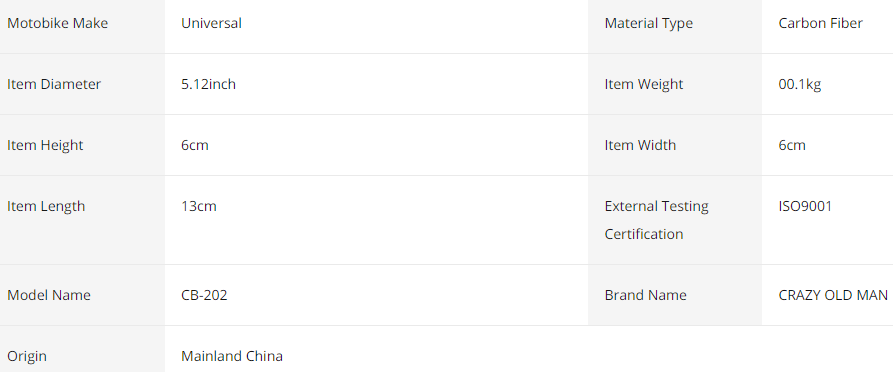

Place of Origin: China

Brand Name: CRAZY OLD MAN

OEM/ODM: Availalbe

Packaging: Foam packing

Transportation: By air, by ship, by train

Application: Modified motorcycle

Payment Method: Alipay, TT, Western Union, Visa, Master Card, Credit Card,

Paypal

Terms of Trade: EXW, FOB, CFR, CIF, DAP, DDP

Supply Capacity: 20000pcs in one month

Quality/Safety Certification: IATF16949:2016 quality management system

Fitment: Universal for all pipe with diameter 4.5-7 cm

Package Includes:

1 Piece Exhaust Muffler Cover

2 Pieces Mounting Accessories

2 Screws

1. High-strength material

The Motorcycle Muffler Cover is made of carbon fiber, a material known for its high strength and low density. Carbon fiber boasts a tensile strength exceeding 3500 MPa, far exceeding that of traditional metals, while maintaining a density of only 1.5-1.7 g/cm³, effectively reducing the weight of motorcycle exhaust pipes. Its excellent heat resistance allows it to withstand high exhaust temperatures over extended periods, while its low coefficient of thermal expansion ensures dimensional stability even under extreme operating conditions.

2. Accurate fit size

The cover is designed to be universal, suitable for exhaust pipes with a diameter of 4.5 - 7cm, covering the size range of most motorcycle exhaust pipes on the market. Five specifications of covers are provided for different exhaust pipe diameters, with a diameter range of 100-150mm, and equipped with silicone gaskets, which can be adjusted within ±2mm to ensure that the cover fits tightly with the exhaust pipe, and will not shake due to being too loose, nor be difficult to install due to being too tight, so as to achieve precise adaptation and meet the personalized needs of different models.

3. Lightweight design

The weight of a single Motorcycle Muffler Cover is only 0.1kg, which is equivalent to the weight of an egg, which has almost no effect on the overall center of gravity and handling performance of the motorcycle. At the same time, the lightweight design of the cover will not increase the burden on the vehicle. In the competition modification, compared with the traditional stainless steel material, the aviation-grade aluminum alloy cover can reduce the weight by 60%, which helps to improve the acceleration performance and handling flexibility of the vehicle, making the motorcycle lighter and more agile during driving, and bringing better driving experience to the rider.

4. High temperature resistance

The temperature resistance range of the cover is - 40℃ to 800℃, which can withstand the instantaneous high temperature impact of the exhaust pipe. When the motorcycle is driven at high speed for a long time or driven vigorously, the exhaust pipe temperature may exceed 600℃, while the built-in insulation layer of the shield (thermal conductivity ≤ 0.03W/m·K) can reduce the surface temperature to below 60℃, effectively preventing burns and fire hazards, ensuring the safety of the rider under various working conditions, and protecting other components around the exhaust pipe from high temperature.

5. Excellent protection level

The protection level of the shield reaches IP67, with excellent dust and water resistance. Under complex road conditions, such as off-road riding, impurities such as mud, sand, and water vapor are difficult to enter the shield, avoiding rust or failure of the exhaust pipe due to internal water ingress or dust accumulation. At the same time, the surface of the shield is treated with a special coating, which has the characteristics of anti-ultraviolet, anti-acid rain and anti-high temperature oxidation. It can effectively resist the aging effect of ultraviolet rays on the material, prevent acid rain from corroding the metal surface, and oxidation reaction in high temperature environment, so that the shield can still maintain good appearance and performance after more than 5 years of outdoor use.

6. Quick installation method

The guard adopts the fixing method of snap + screw, which is compatible with the original exhaust pipe interface and realizes non-destructive installation. No special tools are required during the installation process, and ordinary users can complete the installation or removal within 3 minutes. This convenient installation method is not only convenient for users to operate by themselves, but also convenient for quick removal of the guard when the exhaust pipe needs to be maintained or inspected, which improves the maintenance efficiency of the vehicle and avoids potential damage to the exhaust pipe caused by improper installation.

7. High-precision manufacturing process

The guard is manufactured by precision stamping process, which ensures the structural stability and dimensional accuracy of the product. The precision stamping process can make the metal material deform evenly in the mold to form a precise shape and size, so that all parts of the guard can fit the exhaust pipe tightly and provide uniform protection. At the same time, the high-precision manufacturing process also ensures the appearance quality of the guard, the surface is flat and smooth, without defects and burrs, which improves the overall aesthetics of the product and complements the overall design of the motorcycle.

8. Long-life design

The surface coating of the Motorcycle Muffler Cover adopts the electrophoretic coating process, and the coating thickness is uniform, the adhesion is strong, and it has excellent corrosion resistance. After 1000 hours of salt spray test, the coating did not rust, ensuring that the cover can be used outdoors for more than 3 years without rust problems. In addition, the material and structural design of the cover also take into account the reliability of long-term use. Even under frequent temperature changes and mechanical vibrations, it can still maintain stable performance, providing long-term and reliable protection for the motorcycle exhaust pipe, reducing the user's maintenance cost and replacement frequency

1. Off-road riding and rally

In complex off-road conditions, such as mountains and deserts, motorcycle exhaust pipes are extremely vulnerable to flying stone impacts and tree branch scratches. At this time, the high-strength aluminum alloy material (thickness ≥ 2mm) of the Motorcycle Muffler Cover can withstand 50J of impact energy, effectively preventing the exhaust pipe from being dented or punctured. At the same time, the anti-slip texture design on the surface of the cover can reduce the adhesion of mud and sand in the mud and sand environment, reduce the risk of exhaust pipe overheating caused by mud and sand accumulation, ensure the normal operation of the motorcycle under harsh road conditions, and provide reliable safety protection for off-road riding and rally.

2. Urban commuting and daily travel

In urban commuting and daily travel, motorcycles are exposed to humid and salt spray environments for a long time, especially in coastal cities, where exhaust pipes are easily corroded and rusted by salt spray. The 304 stainless steel cover with electrophoretic coating can withstand salt spray for more than 500 hours, and the annual corrosion rate is less than 0.01mm. This excellent corrosion resistance can effectively resist salt spray erosion and extend the service life of the exhaust pipe. At the same time, the matte black / titanium gray exterior design of the cover enhances the texture of the vehicle, reduces the visual pollution of the vehicle in the urban environment, and makes the motorcycle more fashionable and modern on the city streets.

3. Long-distance motorcycle travel and adventure riding

During long-distance motorcycle travel and adventure riding, continuous driving will cause the exhaust pipe temperature to exceed 600℃, posing a scalding or fire hazard. The built-in insulation layer of the Motorcycle Muffler Cover (thermal conductivity ≤ 0.03W/m·K) can reduce the surface temperature of the exhaust pipe to below 60℃, effectively preventing scalding and fire accidents. In addition, the drainage hole design at the bottom of the cover can timely remove condensed water and avoid corrosion problems caused by water accumulation around the exhaust pipe, thereby extending the service life of the exhaust pipe, providing safety protection for long-distance travel and adventure riding, and ensuring that riders can enjoy the journey with peace of mind.

4. Racing modification and performance improvement

In the field of racing modification, vehicles need to reduce non-suspension mass and improve heat dissipation efficiency. The density of the aviation-grade aluminum alloy shield is 2.7g/cm³, which is 60% lighter than traditional stainless steel. At the same time, the shield adopts a hollow heat dissipation hole design, which increases air circulation and reduces exhaust pipe back pressure, thereby increasing engine power output by 5% - 8%. This performance improvement is crucial to the performance of the car on the track, enabling the car to achieve better acceleration performance and fuel economy, and gain an advantage in competitive racing competitions.

5. Retro models and custom modifications

For classic retro models, such as Harley and BMW R series, it is necessary to retain the original design language when modifying, while improving protection performance. The shield provides surface treatment processes such as laser engraving, chrome plating, and brushing, which can perfectly adapt to the style of retro models. In addition, the 3D printed custom interface, with an error control of ≤ 0.1mm, realizes non-destructive installation, which not only retains the classic appearance of the retro model, but also provides modern protection for its exhaust pipe, so that the retro model has higher reliability and safety while maintaining its original charm.

6. Special environment operation

In some special environments, such as industrial or chemical areas, motorcycle exhaust pipes may be corroded by corrosive substances such as acidic gases and chemical reagents. The IP67 protection level and special surface coating of the Motorcycle Muffler Cover can effectively resist the invasion of these corrosive substances. Its resistance to acid rain and high temperature oxidation enables the cover to maintain good performance in an environment containing acidic gases, preventing the exhaust pipe from being corroded and damaged. At the same time, the sealing structure of the cover can prevent chemical reagents from entering the exhaust pipe, ensuring the normal operation of the motorcycle in special environments, and providing all-round protection for motorcycles working in these environments.

1. Cleaning and Maintenance

After daily use, use a soft brush to remove sand and dust from the surface of the Motorcycle Muffler Cover to prevent hard objects from scratching the coating. After every 5,000 kilometers, use a neutral detergent with a pH value of 6 - 8 for wiping and cleaning. Avoid using chlorine or acidic solvents, as these chemicals will destroy the chemical structure of the coating, causing the coating to age, discolor, or even peel off. When cleaning, use a gentle wiping action and avoid excessive force to avoid mechanical damage to the coating. After cleaning, rinse with clean water and wipe dry with a clean soft cloth to ensure that there is no detergent residue on the surface of the cover to keep the cover clean and the coating intact.

2. Regular inspection

After every 10,000 kilometers, it is necessary to check whether the fixing screws of the cover are loose. The recommended torque value is 8 - 10N·m. Use a torque wrench to tighten according to the specified torque value to avoid the shield from shaking during driving due to loose screws, affecting the fit between the shield and the exhaust pipe, and thus reducing the protective effect. At the same time, observe whether the coating has fallen off and check whether there are signs of rust on the surface of the exhaust pipe. For stainless steel shields, the inspection cycle can be extended to 20,000 kilometers. If a small area of coating is found to have fallen off, it should be repaired in time to prevent further expansion of rust and affect the protective performance and service life of the shield.

3. Storage environment

When the motorcycle is parked for a long time, the shield should be wrapped with a dust cover to prevent ultraviolet rays from directly irradiating the surface of the shield. Ultraviolet rays will accelerate the aging of the coating, causing the coating to harden, crack or even peel off, thereby reducing the protective performance of the shield. The humidity of the storage environment should be controlled at ≤ 60%, the temperature range should be between - 20℃ and 50℃, and away from corrosive gases such as hydrogen sulfide. High humidity environment will accelerate the corrosion process of metal, while extreme temperature may change the material properties, affecting the structural stability and protective performance of the cover. Choosing a suitable storage environment can effectively extend the service life of the cover and ensure that it can still function normally when it is used next time.

4. Deformation repair

If the Motorcycle Muffler Cover is deformed due to an accidental collision, it can be corrected using a hydraulic press. During correction, the pressure of the hydraulic press should be controlled at ≤ 50MPa to avoid excessive stress damage to the material. After correction, the dimensional tolerance of the cover needs to be remeasured to ensure its adaptability to the exhaust pipe. The dimensional tolerance should be within the specified range to ensure that the cover fits tightly with the exhaust pipe and provides effective protection. At the same time, the corrected cover should be inspected for appearance to ensure that there are no obvious signs of deformation on its surface and maintain a beautiful appearance.

5. Coating repair

When the coating of the cover is damaged and needs to be repaired, the cover should be sent back to the manufacturer for professional repair. The repair process includes sandblasting (roughness Ra ≤ 3.2μm) and re-electrophoresis coating. Sandblasting can remove damaged coatings and surface impurities, providing a good adhesion foundation for new coatings. The coating performance of the shield after re-electrophoretic coating should be close to or reach the standard of new products. The repair cost is about 30% of the price of new products, which is more economical than replacing new shields. Through professional coating repair, the protective performance and appearance of the shield can be restored and its service life can be extended.

6. Seasonal maintenance

The maintenance focus of motorcycle exhaust pipe shields is different in different seasons. In winter, due to the low temperature, the toughness of the material will decrease. The inspection of the shield should be strengthened to ensure that it is free of cracks or damage. At the same time, pay attention to clearing ice and snow on the surface of the shield to prevent ice and snow from melting and entering the shield to corrode the exhaust pipe. In summer, the high temperature environment will increase the temperature of the shield. In addition to daily cleaning and inspection, attention should also be paid to the heat dissipation of the shield to ensure that its heat dissipation holes are unobstructed to avoid excessive temperature of the exhaust pipe due to poor heat dissipation. In the rainy season, the moisture-proof treatment of the shield should be strengthened, and the drainage holes should be checked to prevent rainwater from accumulating inside the shield and causing rust in the exhaust pipe. Through maintenance measures tailored to the characteristics of different seasons, the performance of the guard can be better maintained, its service life can be extended, and the normal use of the motorcycle in various seasons can be ensured.

A: The hollow design improves the heat dissipation efficiency by 15%, and the surface temperature is 40℃ lower than that of the unprotected state (actual measured data).

A: Five specifications with diameters of 100-150mm are provided, and the error can be adjusted through silicone gaskets within ±2mm.

A: The electrophoretic coating has passed the 1000-hour salt spray test and has no rust for 3 years of outdoor use (according to ISO 9227 standard).

A: It is fixed with buckles + screws, compatible with the original exhaust pipe interface, and can be installed non-destructively within 3 minutes.

A: A single piece is only 0.1kg, equivalent to the weight of an egg, and the impact on the center of gravity of the vehicle is negligible.

———————————————————————————————————————————————————————————————

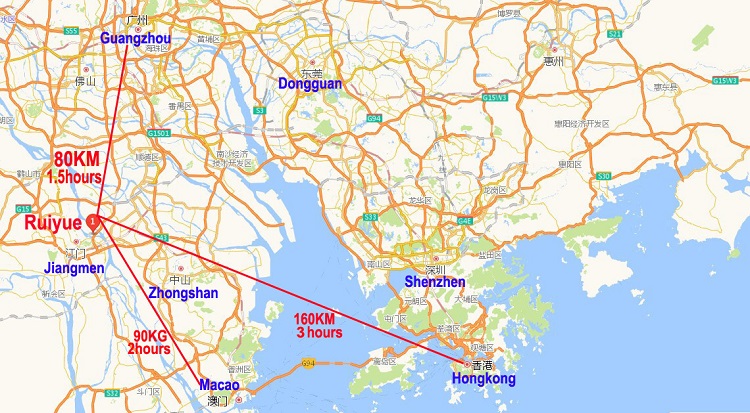

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information