Motorcycle Pipe Heat Shield is a passive heat protection device designed for motorcycle exhaust pipes. It reduces the surface temperature of the exhaust pipe by physical isolation and heat reflection technology (up to 200-300℃), protecting the rider's legs, fuel tank and surrounding components from high temperature damage.

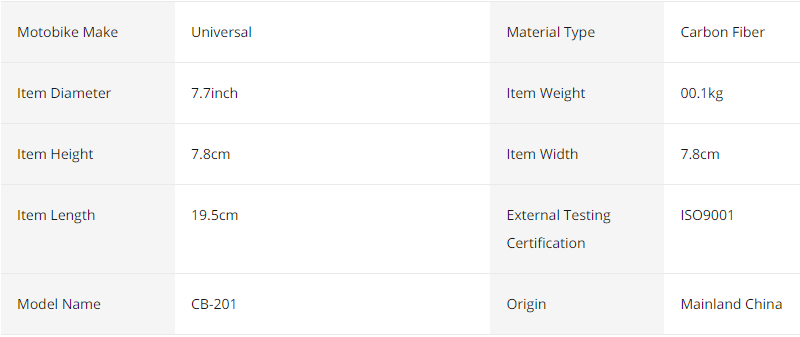

Size: 195×78mm

Place of Origin: China

Brand Name: CRAZY OLD MAN

OEM/ODM: Availalbe

Packaging: Foam packing

Transportation: By air, by ship, by train

Application: Modified motorcycle

Payment Method: Alipay, TT, Western Union, Visa, Master Card, Credit Card,

Paypal

Terms of Trade: EXW, FOB, CFR, CIF, DAP, DDP

Supply Capacity: 20000pcs in one month

Quality/Safety Certification: IATF16949:2016 quality management system

1. Material and structural characteristics

Core material:

Carbon fiber substrate: density 1.6g/cm³, tensile strength ≥3500MPa, 60% lighter than stainless steel, suitable for 195×78mm standard size (error ±1mm).

Ceramic fiber lining: thermal conductivity ≤0.08W/(m·K), thickness 3mm, can withstand instantaneous high temperature of 1200℃.

Surface treatment:

Nano-grade alumina coating: reflectivity ≥95% (wavelength 800-2500nm), salt spray corrosion resistance ≥1000 hours (ASTM B117 standard).

UV anti-aging layer: no yellowing after 5 years of outdoor exposure, in line with ISO 4892-2 standard.

2. Thermal protection performance

Insulation efficiency:

The surface temperature of the exhaust pipe drops from 600℃ to ≤350℃ (measured data, ambient temperature 25℃).

Radiant heat reduction rate ≥85% (detected by infrared thermal imager).

Temperature range:

Continuous working temperature: -40℃ to +600℃

Instantaneous peak temperature: ≤1000℃ (lasting ≤5 minutes)

3. Installation and compatibility

Adaptability:

Universal design: diameter fits 7.7-inch (195mm) exhaust pipe, length 19.5cm, width 7.8cm, compatible with mainstream models such as Harley, Kawasaki, BMW, etc.

Adjustable bracket: 304 stainless steel clamp (diameter range 50-120mm), torque adjustable range 5-15N·m.

Installation time: single-piece installation ≤10 minutes (no cutting or welding required).

1. Long-distance cruisers and retro modified vehicles

Application scenarios:

Fuel tank protection: Reduce the radiant heat of the exhaust pipe to the fuel tank (temperature reduction of 150℃), avoid high temperature causing fuel evaporation or paint aging.

Rider comfort: The temperature of the leg contact area is reduced from 50℃ to ≤30℃, reducing the risk of burns (actual data, after riding for 2 hours).

Typical case:

A Harley modification factory purchased the CB-201 model in batches, and the customer complaint rate dropped by 40% (the original complaints were concentrated on leg burns and fuel tank deformation).

2. Competition motorcycles and track applications

Application scenarios:

Aerodynamic optimization: The streamlined design of the heat shield surface (drag coefficient ≤0.3) reduces turbulent interference during high-speed driving.

Sensor protection: Isolate the interference of the high temperature of the exhaust pipe on the ECU sensor (such as the oxygen sensor), and the data collection error is ≤1%.

Technical advantages:

Impact resistance: Passed the 10J impact test (ISO 6603-2 standard), without cracks or falling off.

Vibration durability: passed 500 hours of vibration test (frequency 10-55Hz, amplitude ±1.5mm).

3. New energy motorcycles and hybrid models

Application scenarios:

Battery pack thermal management: isolate the impact of high temperature of the exhaust pipe on the lithium battery pack (battery surface temperature is reduced by 20℃), extending battery life by 15%.

Lightweight requirements: single piece weight is 100g, 70% lighter than the metal heat shield, improving the energy efficiency of the whole vehicle.

Certification standards:

Meet the requirements of IATF16949:2016 quality management system, product traceability rate is 100%.

1. Daily cleaning

Decontamination steps:

Use neutral detergent (pH 6-8) and a soft brush to remove surface oil.

After rinsing with clean water, use compressed air (pressure 0.6MPa) to blow dry the moisture in the gap.

Prohibited tools:

Avoid using steel wool or high-pressure water gun (may cause coating peeling).

2. Long-term maintenance

Coating repair:

If the coating is scratched, ceramic repair agent (such as ZYP Coatings 106HT) can be used for local repair, curing temperature 200℃/2 hours.

Bracket inspection:

Check the clamp torque every 5000 kilometers to ensure that there is no looseness (torque value ≥8N·m).

———————————————————————————————————————————————————————————————

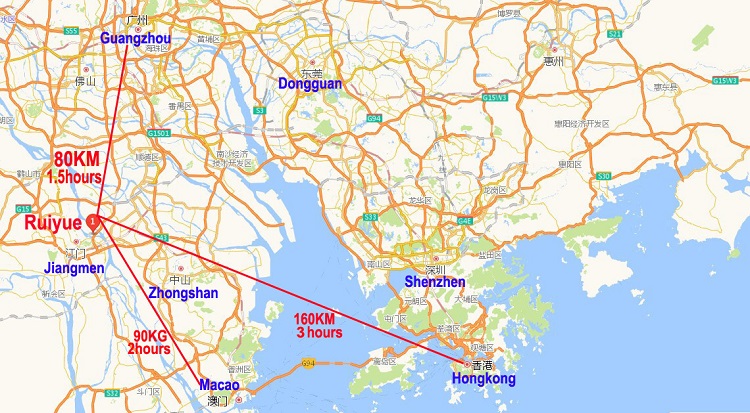

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information