Motorcycle Backrest Cushion is a riding accessory designed to improve rider comfort and lumbar support. It reduces spinal pressure during long-distance riding through adjustable brackets and ergonomic shock-absorbing materials.

1. Structure and support performance

Core material:

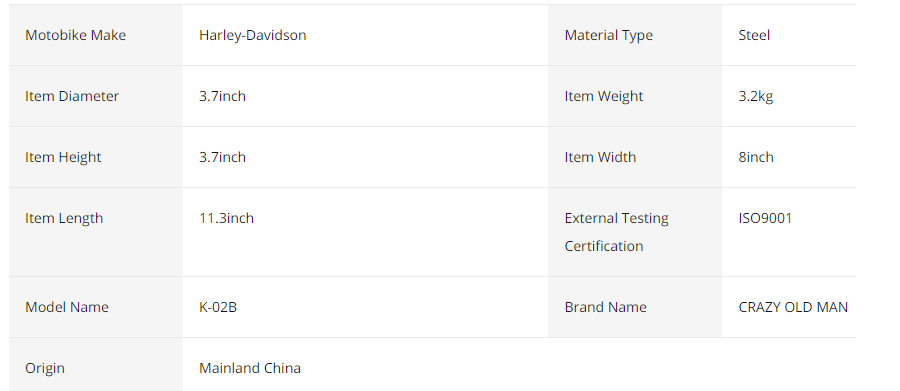

Steel skeleton: 3.7-inch (94mm) diameter galvanized steel pipe, wall thickness 2mm, bending strength ≥1500N, passed SGS 100,000 fatigue tests.

Memory foam filling: thickness 50mm, rebound time ≤3 seconds, hardness 45±5 Shore C, in line with the physiological curvature of the human lumbar spine (radius 150mm).

Adjustment function:

Angle adjustment: 0-25° stepless adjustment (damping torque 1.5-2.5N·m), suitable for different riding postures.

Height adjustment: supports 3 levels of lifting (stroke ±40mm), suitable for riders with a height of 160-190cm.

2. Comfort and durability

Surface material:

Anti-slip leather: friction coefficient ≥ 0.8 (ASTM D1894 standard), tear strength ≥ 50N/mm, UV resistance level 8 (ISO 105-B02).

Breathable mesh: porosity ≥ 60%, heat dissipation efficiency increased by 40% at a wind speed of 3m/s, reducing sweat accumulation.

Safety certification:

Passed the ECE R22.05 motorcycle accessories safety standard, impact energy ≥ 50J (10kg hammer free fall from a height of 50cm).

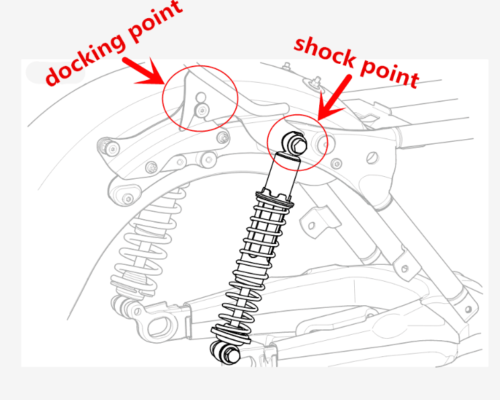

3. Installation and compatibility

Applicable models:

Universal design: compatible with Harley-Davidson Touring series (such as Electra Glide, Street Glide) and Indian Chief models, bracket hole spacing 200±5mm.

Quick installation: adopts a welding-free buckle structure, and the installation time of a single piece is ≤ 15 minutes (the tool only requires a wrench).

Load capacity:

Static load ≥ 150kg, dynamic load ≥ 100kg (simulated riding bump test).

1. Long-distance cruising and travel riding

Optimized lumbar support: Disperse lumbar pressure through memory foam (pressure distribution uniformity increased by 25%), reducing fatigue after 2 hours of riding.

Luggage fixation: The top of the backrest is integrated with strap holes (diameter 12mm), which can fix backpacks below 20L to prevent slipping during riding.

2. Police and official motorcycles

Integration of law enforcement equipment: MOLLE system mounting points are reserved on both sides of the backrest, which can carry equipment such as walkie-talkies and batons (load ≤ 5kg).

Impact protection: During pursuit or emergency braking, the backrest absorbs part of the impact force (shock absorption efficiency ≥ 35%), reducing the risk of spinal injury for riders.

3. Retro modification and customized models

Styling modification: Provide 3 surface treatments: chrome plating, matte black, and antique copper, matching the styles of models such as Bobber and Chopper.

Lightweight requirements: Through topological optimization design, the weight of the bracket is 20% lighter than that of traditional products (total weight 3.2kg), which is suitable for the trend of lightweight modification.

Certification standards:

Comply with IATF16949:2016 quality management system, product traceability rate is 100%, and customized LOGO laser engraving is supported.

1. Daily cleaning

Decontamination steps:

Use a neutral detergent (pH value 6-8) and a soft brush to remove dust from the leather surface.

Use a vacuum cleaner (power ≥1200W) at low gear to clean the mesh area to avoid fiber entanglement.

Prohibited tools:

Avoid using detergents containing alcohol or solvents (may cause leather hardening).

2. Long-term maintenance

Leather maintenance:

Apply a special leather care agent (such as Lexol PH balancer) every 3 months to maintain flexibility and prevent cracking.

Bracket anti-rust:

Check the integrity of the galvanized layer every year. If rust spots appear, sandpaper (mesh number ≥400) should be used to polish and then spray anti-rust paint.

Q1: Will the backrest affect the rider's control flexibility?

A: No. The distance between the backrest and the fuel tank is ≥80mm, and the bracket adopts a low center of gravity design. The measured turning radius is consistent with the original car (error ≤0.5m).

Q2: Can it be adapted to other brands of models?

A: It can be compatible with Honda Gold Wing, BMW K1600 and other models by replacing the bracket adapter (extra charge), and the adaptation period is 7-10 days.

Q3: Will the memory foam deform due to high temperature?

A: Through the 70℃/72-hour high temperature aging test, the thickness change rate is ≤2%, and the recovery rate is ≥98%.

Q4: Is the product environmentally certified?

A: It complies with REACH regulations, the content of polycyclic aromatic hydrocarbons (PAHs) is ≤1mg/kg, and phthalates (6P) are not detected.

Q5: How to avoid damage during transportation?

A: Double-layer corrugated box (compressive strength ≥ 1500N) and EPE foam lining (thickness ≥ 50mm) are used. The drop test passes the ISTA 1A standard.

———————————————————————————————————————————————————————————————

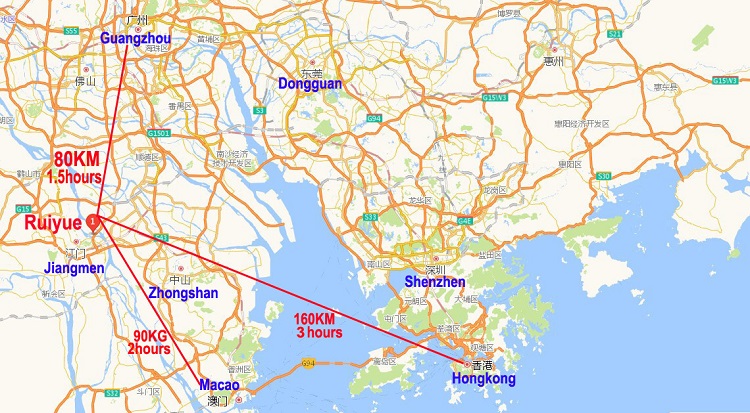

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information