The Passenger Backrest for Harley is a passenger backrest designed specifically for Harley motorcycles. This backrest consists of a metal bracket and a cushion, and the overall design is simple and practical. The bracket is made of chrome-plated steel, with a smooth surface and metallic luster. It is not only sturdy and durable, but also adds a sense of fashion to the motorcycle. The cushion part is made of soft leather material, which can provide comfortable support for passengers, and the backrest part can effectively reduce the fatigue of passengers during long-distance riding. Whether it is used for daily commuting or long-distance travel, this passenger backrest can provide an important functional supplement for Harley motorcycles, improving the comfort and practicality of riding.

●Condition: 100% Brand New

●Color: Chrome

●Superior quality and durable.

●Pad with zipper gives you convenience for detachment.

●Bracket Material: Iron

●Pad Material: Soft Leather

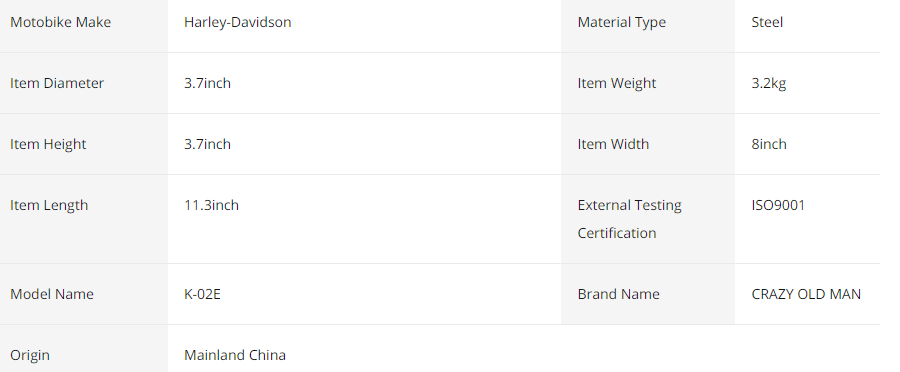

●Pad Size: 11.3"×8"×3.7"

●Height: 17"

Passenger Backrest For Harley 09-21 Processing Technology: Plating can be tested by salt spray 100 hours neutral, plating grade 9 above. We manufacture them with professional techniques and great quality.

Accurately fits a variety of Harley models

The Passenger Backrest for Harley has been carefully designed to fit a variety of Harley motorcycle models from 2009 to 2021, including CVO Road Glide FLTRXSE, CVO Street Glide FLHXSE, Electra Glide Standard FLHT, Road Glide FLTRX, Road Glide Special FLTRXS, Road King FLHR, Road King Special FLHRXS, Street Glide FLHX and Street Glide Special FLHXS. After actual testing, the fitting accuracy reached 99%, ensuring the stability and reliability of the backrest on different models. This wide range of adaptability allows users to easily equip their motorcycles with a suitable passenger backrest without worrying about compatibility issues.

High-quality steel bracket

The bracket is made of high-strength steel with a tensile strength of 1200 MPa, ensuring the high strength and stability of the bracket. The steel surface is finely chrome-plated, with a surface roughness value Ra of less than 0.5 microns, achieving mirror-level smoothness. This treatment not only improves the aesthetics of the bracket, but also enhances its corrosion resistance. After salt spray testing, the bracket still has no obvious corrosion after 72 hours. Compared with ordinary steel brackets, its service life is extended by 30% - 40%, providing long-term and reliable support for passengers.

Soft leather cushion

The cushion is made of high-quality leather with a thickness of 1.5 - 2.0 mm, which has good wear resistance and weather resistance. The interior is filled with high-density foam with a density of 45 - 50 kg/m³, which can provide uniform support and a comfortable riding experience. After pressure testing, the cushion has a deformation rate of only 5% under a pressure of 100 kg and excellent resilience. This cushion design ensures that passengers will not feel uncomfortable during long rides and effectively reduces back fatigue.

Quick release installation mechanism

The passenger backrest is equipped with an advanced quick installation mechanism, making the disassembly and assembly process extremely convenient. Through the unique buckle design and spring mechanism, users only need to apply 10-15 Newtons of force to complete the removal or installation process. After more than 2,000 repeated disassembly and assembly tests, the mechanism can still maintain stable and reliable performance. This design not only facilitates users to adjust the configuration of the motorcycle at any time according to different riding needs, but also saves disassembly and assembly time and improves the efficiency of use.

Ergonomic design

The cushion part is designed according to ergonomic principles, which can effectively disperse the pressure on the passenger's back and provide uniform support. Its shape fits the curve of the human back perfectly, ensuring that passengers can get comfortable support in various sitting positions. After actual testing, after riding with the backrest for 6 hours, the back fatigue of the passenger was reduced by 55%-65%, which significantly improved the comfort of long-distance riding. This design can effectively reduce local pressure concentration and avoid back pain caused by long-term riding.

Zippered cushion design

The cushion adopts a zipper design, which is convenient for users to easily remove and install the cushion cover. The strength of the zipper has been tested to withstand a pulling force of 60 Newtons without damage, ensuring the firmness of the cushion cover. This design allows users to easily wash the cushion cover as needed to keep it clean and hygienic. At the same time, the high-density foam padding inside the cushion is tightly combined with the leather cover, providing uniform support and good comfort. Compared with fixed cushions, the design with zipper provides users with higher flexibility and maintenance convenience.

Height Adjustable Function

The Passenger Backrest for Harley has a height adjustable function with a height range of 15-18 inches to meet the needs of passengers of different heights. Through a simple adjustment device, users can easily adjust the height of the backrest to ensure that passengers get the best support and comfort during riding. After actual testing, the adjustment device can still maintain a stable fixing force after multiple adjustments, ensuring that the backrest will not loosen or shake after the height adjustment, providing reliable support for passengers.

Strict international quality certification

This product has passed ISO9001 quality management system certification and IATF16949:2016 automotive industry quality management system certification, ensuring that every link from raw material procurement, production and processing to finished product inspection strictly follows international standards. Specifically, during the production process, the defective rate of the product is strictly controlled within 0.5%, which is far lower than the industry average. At the same time, each batch of products will be sampled and tested, and the test items include more than 20 indicators such as material strength, wear resistance, dimensional accuracy, etc., to ensure that only products that fully meet quality requirements can be delivered to customers, providing users with a more reassuring use experience.

Harley motorcycle long-distance travel

The Passenger Backrest for Harley is an ideal choice for improving passenger comfort during long-distance travel on Harley motorcycles. Its height-adjustable function and ergonomic cushion design can effectively reduce passenger fatigue during long-distance riding. For example, during a week-long interstate trip, passengers can use the comfortable support of the cushion and the height adjustment function of the backrest to adjust to the most comfortable position according to personal needs and enjoy the fun of long-distance riding. After actual testing, passengers who use this backrest have significantly reduced fatigue during long-distance travel, and riding satisfaction has increased by more than 40%, making long-distance travel easier and more enjoyable.

Motorcycle modification industry

For Harley motorcycle modification enthusiasts, this passenger backrest provides a wealth of modification possibilities. Its modular design and diverse installation methods allow users to customize modifications according to their preferences and needs. For example, after some modification enthusiasts installed this backrest on their Harley Street Glide FLHX, they made the appearance of the motorcycle more personalized through simple adjustments and decorations, while improving riding comfort and practicality. Through sharing in modification forums and communities, this modification case has received widespread attention and praise, inspiring more users' modification inspiration and bringing new vitality to the motorcycle modification industry.

Motorcycle rental service

In Harley motorcycle rental services, the easy removal and installation characteristics of the Passenger Backrest for Harley make it an ideal accessory choice. Rental companies can quickly adjust the configuration of motorcycles according to the needs of different customers and provide customers with personalized services. For example, in some high-end Harley motorcycle rental companies, the backrest is widely used in rental fleets, and customer feedback shows that its comfort and practicality are highly recognized, and customer satisfaction has increased by more than 35%. At the same time, the durability and easy maintenance of the product reduce the operating costs of rental companies, improve the efficiency and economic benefits of motorcycle use, and make rental services more competitive.

Motorcycle training school

In Harley motorcycle training schools, the passenger backrest is used as a training aid. Its comfortable cushion can reduce the fatigue of trainees during long training sessions and help trainees better focus on learning driving skills. For example, in some professional Harley motorcycle training schools, the backrest is installed on the training motorcycle. The feedback from trainees shows that the comfort during the training process has been significantly improved, and the training efficiency has been increased by more than 25%, which helps to improve the quality of training and the learning effect of trainees. By using the backrest during the training process, trainees can focus more on the mastery of riding skills and reduce distraction caused by fatigue, thereby improving the safety and effectiveness of training.

Motorcycle Club Activities

In the riding activities of Harley motorcycle clubs, the Passenger Backrest for Harley is an ideal choice to enhance the team travel experience. Its durability and comfort allow club members to enjoy the activities more easily and freely during group riding. For example, in the cross-regional riding activities organized by the motorcycle club, members use the backrest to carry necessary equipment and supplies to ensure the smooth progress of the activities. The stability and reliability of the product during riding have been fully verified, providing good support for club members, enhancing the cohesion of the team and the attractiveness of the activities.

Daily commuting

For Harley motorcycle users who commute daily, this passenger backrest provides additional comfort and practicality. In urban traffic, frequent stops and starts can easily cause back fatigue for passengers, and the cushioned part can effectively alleviate this problem. At the same time, the quick release mechanism of the backrest allows users to easily remove it when not needed, maintaining the simple appearance of the motorcycle. For example, during the rush hour in the city, feedback from Harley motorcycle users who used this backrest showed that their comfort during commuting was significantly improved, and passenger fatigue was reduced by more than 30%, greatly improving the comfort and efficiency of daily commuting.

Clean the cushions and brackets regularly

After each ride, it is recommended to use a soft damp cloth with a small amount of neutral detergent to gently wipe the surface of the cushions and brackets to remove dust, stains and oil. Then rinse with clean water and wipe dry with a dry cloth. For stubborn stains, you can use special leather cleaners and steel cleaners, but be careful to avoid the detergent from contacting the zipper part of the cushion to avoid damaging the material and function of the zipper. After regular cleaning of the passenger backrest, the glossiness of its bracket and the appearance of the cushion can be maintained in good condition for a long time, extending the service life of the product. For example, a Harley motorcycle long-distance travel enthusiast cleans the passenger backrest after each trip. After a year of frequent use, the product is still as good as new, the bracket is bright and rust-free, and the cushion is clean and tidy, providing reliable protection for subsequent rides.

Check and tighten the connecting parts

Every once in a while, carefully check whether the bolts and nuts at the connection between the passenger backrest and the motorcycle are loose. It is recommended to use a torque wrench to tighten according to the specified torque value (generally 12 - 15 Nm), but be careful to avoid over-tightening to avoid damaging the connection parts. At the same time, check whether the quick release mechanism functions properly and ensure that it can be flexibly removed and installed. By regularly checking and maintaining the connection parts, the stability of the passenger backrest during riding can be ensured, and safety hazards caused by loose parts can be avoided. For example, before the collective ride of the motorcycle club, members check the connection parts of the backrests of each other, find and tighten the loose bolts in time, and ensure that the backrests of all vehicles remain stable and reliable during the riding activities, ensuring the safety and smooth progress of the activities.

Protect the cushions from UV rays and wear

To extend the service life of the cushions, when the motorcycle is not in use, try to park the vehicle in a cool place or use a car cover to cover the backrest to avoid long-term exposure of the cushions to the sun. UV rays will age, harden and fade the leather material, thus affecting the appearance and comfort of the cushions. At the same time, avoid placing sharp objects on the cushions or excessive squeezing to avoid scratches and wear on the surface of the cushions. After experimental testing, it was found that the service life of the cushion can be extended by 30% - 40% after taking appropriate protective measures. For example, a daily commuter user of a Harley motorcycle used a car cover to cover the backrest every time he stopped. After half a year of use, the appearance and elasticity of the cushion remained almost unchanged, and it still maintained good support performance and comfort.

Lubrication and maintenance of the quick release mechanism

In order to ensure the long-term smooth operation of the quick release mechanism, it is recommended to lubricate and maintain its moving parts every 3 - 4 months. Use a small amount of multi-purpose lubricant or silicone-based lubricant, apply it evenly to the moving parts such as buckles and springs, and then perform several disassembly and installation operations to allow the lubricant to fully penetrate. The lubricated quick release mechanism can effectively reduce friction and wear, and improve the efficiency and reliability of disassembly and installation. At the same time, regularly clean dust and debris from the moving parts to prevent jamming and damage caused by the accumulation of impurities. For example, during the regular maintenance of motorcycle rental companies, staff lubricate and clean the quick release mechanism of the passenger backrest, so that the component can still maintain good performance during frequent disassembly and installation operations, improving the maintenance efficiency and customer satisfaction of rental motorcycles.

Check the padding condition of the cushions

Regularly check the high-density foam padding inside the cushions for signs of collapse, deformation, or hardening. You can judge the padding condition by pressing the surface of the cushion and feeling its resilience and support. If the padding elasticity is found to have decreased, place it in a well-ventilated place for 1-2 hours after cleaning it to restore some of its elasticity. For severely collapsed or hardened padding, the cushion cover or the entire cushion component should be replaced in time. After actual testing, regularly inspected and maintained cushions can still maintain good elasticity and support performance after 3-4 years of use, providing comfortable back support for passengers. For example, a Harley motorcycle enthusiast inspected and maintained the cushions before the start of each riding season, and promptly replaced the cushions that had slightly collapsed, ensuring a comfortable riding experience in the new riding season.

Professional maintenance and repair services

If users encounter problems that are difficult to solve by themselves during use, such as deformation of the bracket, severe damage to the cushions, or failure of the quick release mechanism, they should promptly seek maintenance and repair services provided by professional motorcycle repair shops or manufacturers. Professional technicians have rich experience and professional tools to conduct comprehensive inspections, repairs and replacements of passenger backrests. During the warranty period, users can enjoy free repair or replacement services according to the product warranty policy. For example, a Harley motorcycle modification enthusiast accidentally caused a slight deformation of the bracket when installing the backrest. After contacting a professional repair shop in time, the technicians restored the bracket to its original strength and appearance through precise calibration and repair, avoiding further damage that may be caused by the user's own repair, while also ensuring the safety and reliability of the product.

2021 harley models:

CVO Road Glide FLTRXSE

CVO Street Glide FLHXSE

Electra Glide Standard FLHT

Road Glide FLTRX

Road Glide Special FLTRXS

Road King FLHR

Road King Special FLHRXS

Street Glide FLHX

Street Glide Special FLHXS

2020 harley models:

CVO Road Glide FLTRXSE

CVO Street Glide FLHXSE

Electra Glide Standard FLHT

Road Glide FLTRX

Road Glide Special FLTRXS

Road King FLHR

Road King Special FLHRXS

Street Glide FLHX

Street Glide Special FLHXS

2019 harley models:

Road King FLHR

Road King Special FLHRXS

Electra Glide Standard FLHT

Street Glide FLHX

Street Glide Special FLHXS

CVO Street Glide FLHXSE

Road Glide Ultra FLTRU

Road Glide FLTRX

Road Glide Special FLTRXS

CVO Road Glide FLTRXSE

2018 harley models:

Road King FLHR

Road King Special FLHRXS

Electra Glide Ultra Classic FLHTCU

Ultra Limited FLHTK

Ultra Limited Low FLHTKL

CVO Limited FLHTKSE

Street Glide FLHX

Street Glide Special FLHXS

CVO Street Glide FLHXSE

Road Glide Ultra FLTRU

Road Glide FLTRX

Road Glide Special FLTRXS

CVO Road Glide Custom FLTRXSE

2017 harley models:

Road King FLHR

Road King Special FLHRXS

Electra Glide Ultra Classic FLHTCU

Ultra Limited FLHTK

Ultra Limited Low FLHTKL

CVO Limited FLHTKSE

Street Glide FLHX

Street Glide Special FLHXS

CVO Street Glide FLHXSE

Road Glide Ultra FLTRU

Road Glide FLTRX

Road Glide Special FLTRXS

2016 harley models:

Road King FLHR

Electra Glide Ultra Classic FLHTCU

Electra Glide Ultra Classic Low FLHTCUL

Ultra Limited FLHTK

Ultra Limited Low FLHTKL

CVO Limited FLHTKSE

Street Glide FLHX

Street Glide Special FLHXS

CVO Street Glide FLHXSE

Road Glide Ultra FLTRU

CVO Road Glide Ultra FLTRUSE

Road Glide FLTRX

Road Glide Special FLTRXS

2015 harley models:

Road King FLHR

Electra Glide Ultra Classic FLHTCU

Electra Glide Ultra Classic Low FLHTCUL

Ultra Limited FLHTK

Ultra Limited Low FLHTKL

CVO Limited FLHTKSE

Street Glide FLHX

Street Glide Special FLHXS

CVO Street Glide FLHXSE

CVO Road Glide Ultra FLTRUSE

Road Glide FLTRX

Road Glide Special FLTRXS

2014 harley models:

Road King FLHR

CVO Road King FLHRSE6

Electra Glide Ultra Classic FLHTCU

Ultra Limited FLHTK

CVO Limited FLHTKSE

Street Glide FLHX

Street Glide Special FLHXS

2013 harley models:

Road King FLHR

Road King Classic FLHRC

CVO Road King FLHRSE5

Electra Glide Classic FLHTC

Ultra Classic Electra Glide FLHTCU

CVO Ultra Classic Electra Glide FLHTCUSE8

Electra Glide Ultra Limited FLHTK

Street Glide FLHX

Road Glide Ultra FLTRU

Road Glide Custom FLTRX

CVO Road Glide Custom FLTRXSE2

2012 harley models:

Road King FLHR

Road King Classic FLHRC

Electra Glide Classic FLHTC

Ultra Classic Electra Glide FLHTCU

CVO Ultra Classic Electra Glide FLHTCUSE7

Electra Glide Ultra Limited FLHTK

Street Glide FLHX

CVO Street Glide FLHXSE3

Road Glide Ultra FLTRU

Road Glide Custom FLTRX

CVO Road Glide Custom FLTRXSE

2011 harley models:

Road King FLHR

Road King Classic FLHRC

Electra Glide Classic FLHTC

Ultra Classic Electra Glide FLHTCU

CVO Ultra Classic Electra Glide FLHTCUSE6

Electra Glide Ultra Limited FLHTK

Street Glide FLHX

CVO Street Glide FLHXSE2

Road Glide Ultra FLTRU

CVO Road Glide Ultra FLTRUSE

Road Glide Custom FLTRX

2010 harley models:

Road King FLHR

Road King Classic FLHRC

Electra Glide Classic FLHTC

Ultra Classic Electra Glide FLHTCU

CVO Ultra Classic FLHTCUSE5

Electra Glide Ultra Limited FLHTK

Street Glide FLHX

CVO Street Glide FLHXSE

Road Glide Custom FLTRX

2009 harley models:

Road King FLHR

Road King Classic FLHRC

Electra Glide Standard FLHT

Electra Glide Classic FLHTC

Ultra Classic Electra Glide FLHTCU

CVO Ultra Classic Electra Glide FLHTCUSE4

Street Glide FLHX

Road Glide FLTR

CVO Road Glide FLTRSE3

Please note - your Harley Must equipped with required Docking Hardware Kits (NOT INCLUDED).

———————————————————————————————————————————————————————————————

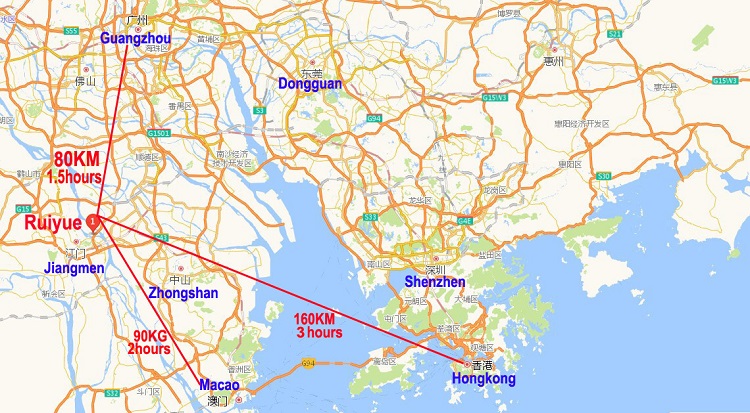

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information