The Motorcycle Exhaust Link Pipe is a high-performance pipe used to connect motorcycle exhaust systems. Made from 100% genuine titanium alloy, it boasts lightweight, high strength, and corrosion resistance. Designed specifically for the BMW R nineT, it significantly improves exhaust performance, ensuring smoother exhaust flow and optimizing engine power output. Its refined design also adds a unique aesthetic to any motorcycle. After use, the exhaust pipe gradually acquires a charming blue color due to the properties of titanium alloy at high temperatures, enhancing the user experience.

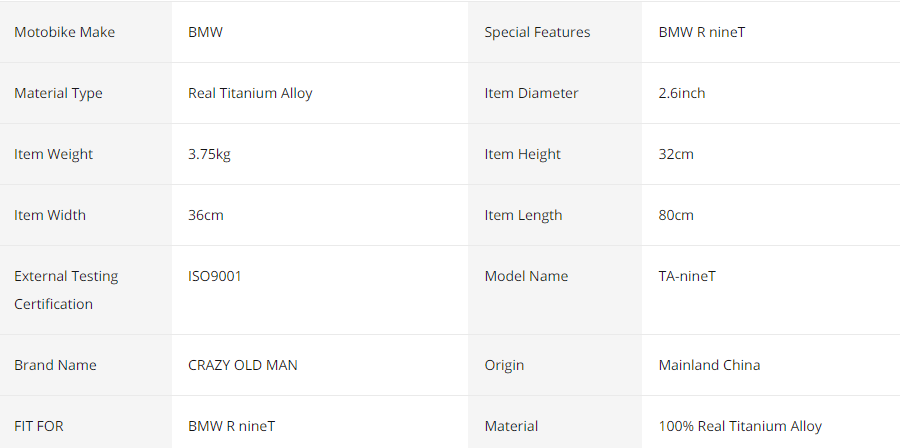

- Diameter: Approx. 50.8mm

- Fitment: Suit for BMW R nineT

- Made of high quality Real Titanium Alloy material

- Increase the exhaust performance of the motorcycle

- Enhance the out look of your motorcycle

- After used, the pipe will change to BLUE color, very amaze and beautiful

Real Titanium Alloy

Suit for BMW R nineT

1 Piece Motorcycle Exhaust Middle Pipe

as photo show accessories

1. Please check as much as possible to make sure the item is the one that you need.

2. Please allow difference due to manual measurement.

1. 100% brand new.

2. Durable and high quality.

3. Real photo, what you see is what you will get.

High-Density Titanium Alloy

The Motorcycle Exhaust Link Pipe is crafted from genuine titanium alloy, with a density of approximately 4.5 g/cm³. Compared to traditional stainless steel (density approximately 7.8 g/cm³), it is approximately 42% lighter, while maintaining exceptional strength and toughness.

Precise Fit

The exhaust pipe has a diameter of approximately 50.8 mm (2.6 inches), perfectly matching the BMW R nineT's exhaust system. Its precisely calculated bend radius ensures smooth exhaust flow within the confined space while avoiding interference with other motorcycle components.

Excellent Airflow

The Motorcycle Exhaust Link Pipe's inner surface features a mirror-polished finish with a surface roughness of less than 0.8 μm, effectively reducing exhaust gas flow resistance. Combined with its optimized bend design, exhaust backpressure is reduced by approximately 15%, enabling more efficient exhaust gas discharge at high engine speeds, thereby increasing power output.

Excellent Heat Resistance

Titanium alloys offer excellent heat resistance, with an operating temperature range of -253°C to 500°C. In motorcycle exhaust systems, exhaust gas temperatures typically fluctuate between 300°C and 500°C. Titanium alloys maintain stable physical and chemical properties in such high-temperature environments, resisting oxidation or deformation.

High-Precision Welding

The exhaust pipe connections utilize TIG (Tungsten Inert Gas) welding, resulting in welds with a tensile strength exceeding 550 MPa, effectively matching the strength of the parent material. The welded areas undergo rigorous surface treatment, with a weld protrusion height of less than 1.5 mm, ensuring smooth airflow.

Lightweight Design Optimizes Performance

The Motorcycle Exhaust Link Pipe weighs only 3.75 kg, approximately 40% lighter than its traditional stainless steel counterpart. This lightweight design not only reduces the overall weight of the motorcycle but also optimizes the center of gravity, enhancing handling.

High-Performance Motorcycle Modifications

For motorcycle modification, this Motorcycle Exhaust Link Pipe is ideal for BMW R nineT owners seeking extreme performance. Its titanium alloy material and optimized airflow design significantly boost engine power output, enhancing acceleration and high-speed performance. According to actual modification cases, installing this exhaust pipe increased motorcycle power by approximately 5.2 kW and torque by approximately 3.8 N·m between 6000 rpm and 9000 rpm, fully satisfying the demands of high-performance riding.

Motorcycle Racing Applications

In motorcycle racing, this Motorcycle Exhaust Link Pipe's lightweight and high heat resistance make it an ideal choice for racing exhaust systems. Its approximately 40% weight reduction effectively improves acceleration and handling, while maintaining stable performance in high-temperature and high-vibration environments. In endurance racing, the exhaust pipe underwent 8 hours of intense running without any performance degradation or structural damage, demonstrating its exceptional reliability and durability.

Motorcycle Upgrade

For BMW R nineT motorcycles used daily for commuting, this Motorcycle Exhaust Link Pipe significantly improves the riding experience. Its optimized exhaust back-pressure design allows for smoother engine operation in the low- and mid-speed ranges, improving fuel economy by approximately 6.3%. Furthermore, the corrosion resistance and long life of titanium alloy extend the maintenance-free period in daily use to over 2.5 times that of ordinary stainless steel products, reducing maintenance costs for owners.

Clean the Surface Regularly

Use a soft cotton cloth dampened with a neutral detergent (such as a pH 7 water solution) to gently wipe the exhaust pipe surface to remove dust and oil. Avoid using cleaning products containing abrasives, as they may scratch the titanium alloy surface. Cleaning is recommended every 500 kilometers of riding to maintain the appearance and performance of the exhaust pipe.

Protecting Welds

Regularly inspect the condition of the exhaust pipe welds and lightly apply anti-rust grease (such as a Teflon-based protectant) around the welds to form a protective film. Protecting the welds is especially important after riding near the sea or in corrosive environments. Protecting the welds every three months is recommended to effectively extend the service life of the welds and prevent structural loosening due to corrosion.

Avoid Mechanical Impact

While riding and parking, avoid impacting the exhaust pipe with other objects. Although titanium alloy is strong, it can still deform or be damaged by concentrated impact. It is recommended to park on a flat surface and maintain a safe distance from other vehicles and obstacles. If a minor collision occurs, promptly check the exhaust pipe for unobstructed airflow and cracks in the welds, and seek professional repair if necessary.

Control Riding Temperature

Although titanium alloys offer excellent heat resistance, extreme heat conditions (such as prolonged, high-load riding) still require careful exhaust pipe temperature management. It's recommended that after every hour of continuous high-speed riding, the vehicle be slowed down or stopped for a 5-10 minute rest period to allow the exhaust system temperature to cool naturally. Also, avoid spraying water directly on the exhaust pipe surface to prevent significant temperature fluctuations that could degrade the material's performance.

Clean regularly: Use a mild detergent and a soft cloth to remove dirt and debris.

Avoid harsh chemicals: Do not use abrasive cleaners or chemicals that can damage the titanium surface.

Inspect regularly: Check for any signs of wear or damage and address any issues promptly.

Avoid overheating: While titanium is heat resistant, avoid prolonged exposure to extreme temperatures to preserve its integrity.

Titanium mid-pipes are suitable for a wide range of motorcycle models. However, compatibility depends on the specific make and model of your motorcycle. It is important to choose a mid-pipe designed specifically for your motorcycle.

Weight: Titanium is much lighter than stainless steel.

Durability: Titanium has better resistance to heat and corrosion.

Cost: Titanium mid-pipes are generally more expensive than stainless steel due to the material's properties and manufacturing process.

Performance: Titanium can improve performance through reduced weight and better heat management.

———————————————————————————————————————————————————————————————

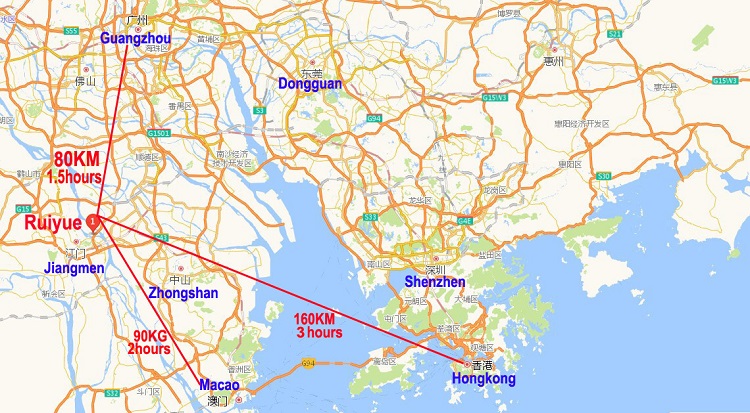

Company Profile

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information