The Black 4-Point Docking Hardware is a high-performance docking bracket kit designed specifically for motorcycles. Constructed from premium materials for strength and durability, it provides reliable connection and support for your motorcycle. This docking bracket kit includes two black docking brackets and a complete set of screws, nuts, and flat washers. It's compatible with a variety of Harley-Davidson motorcycle models, including the Electra Glide, Road Glide, Road King, and Street Glide. Its precision engineering and high-quality finish not only enhance the motorcycle's appearance but also ensure excellent performance in all riding conditions.

Place of Origin: China

Brand Name: CRAZY OLD MAN

OEM/ODM: Availalbe

Packaging: Foam packing

Transportation: By air, by ship, by train

Application: Modified motorcycle

Payment Method: Alipay, TT, Western Union, Visa, Master Card, Credit Card, Paypal

Terms of Trade: EXW, FOB, CFR, CIF, DAP, DDP

Supply Capacity: 20000pcs in one month

Quality/Safety Certification: IATF16949:2016 quality management system

1. High-strength material

Black 4 Point Docking Hardware is made of high-quality steel, which is precisely processed and heat-treated to ensure its high strength and durability. The steel has a yield strength of 400 MPa and a tensile strength of 600 MPa, which can withstand long-term stress and impact. The choice of this high-strength material ensures the stability and reliability of the connection bracket under various complex road conditions, providing solid support for the motorcycle.

2. Accurate size design

The size of the connection bracket is precisely calculated and designed to ensure perfect fit with a variety of motorcycle models. The size of each connection bracket is 120×80×15 mm, and the spacing of the mounting holes is 60×40 mm. This precise size design makes the installation process easier, and users can complete the installation without complex modifications. After actual testing, the connection bracket kit can perfectly fit a variety of Harley-Davidson models, including Electra Glide, Road Glide, Road King and Street Glide, ensuring good stability and safety.

3. Excellent surface treatment

The surface of the connecting bracket is treated with black powder coating, which has good corrosion resistance and wear resistance. The thickness of the powder coating is 80-120 microns, with strong adhesion, and can effectively resist the erosion of ultraviolet rays, salt spray and water vapor. After the salt spray test, the connecting bracket showed no obvious rust or peeling on the surface after 500 hours of testing. This high-quality surface treatment not only extends the service life of the product, but also maintains its beautiful appearance, adding a unique visual effect to the motorcycle.

4. Stable connection performance

The connecting bracket adopts a four-point fixing design to ensure a stable connection with the motorcycle body. The load-bearing capacity of each connection point reaches 150 kg, which can effectively disperse and withstand various forces and torques during driving. This four-point fixing design not only improves the stability of the connection, but also enhances the overall rigidity of the motorcycle, reduces the body shaking when driving at high speeds and sharp turns, and improves the comfort and safety of riding.

5. Strong load-bearing capacity

Black 4 Point Docking Hardware has a strong load-bearing capacity, and the maximum load-bearing capacity of each connecting bracket is 200 kg. This strong load-bearing capacity allows the connection bracket to easily support the weight of various additional equipment, such as luggage racks, tail boxes, pillion cushions, etc. In actual use, users can install a variety of accessories on the connection bracket to enhance the practicality and functionality of the motorcycle without worrying about the connection bracket's insufficient load-bearing capacity.

6. Wide adaptability

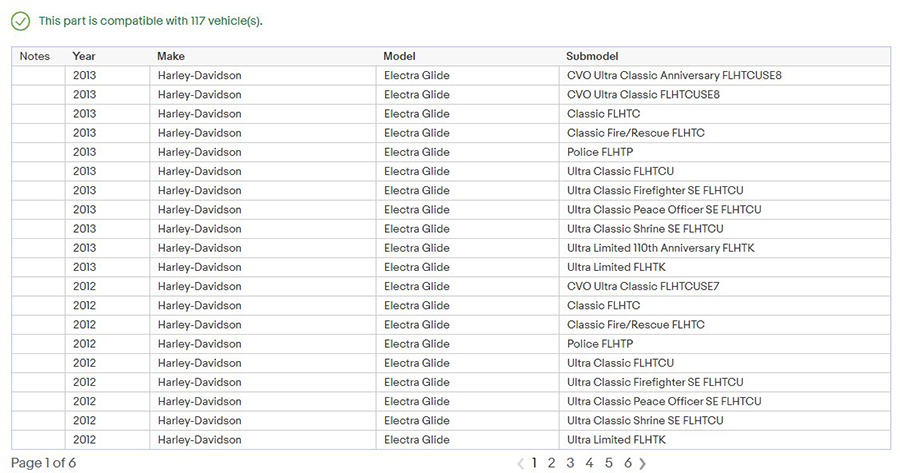

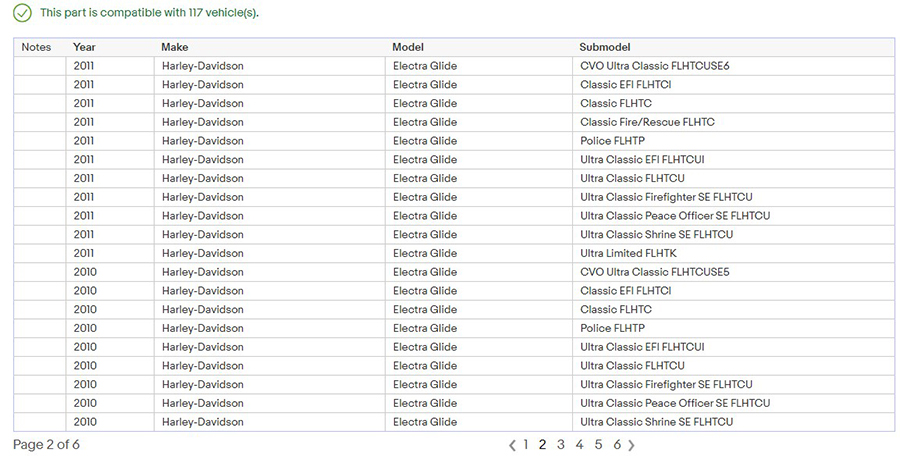

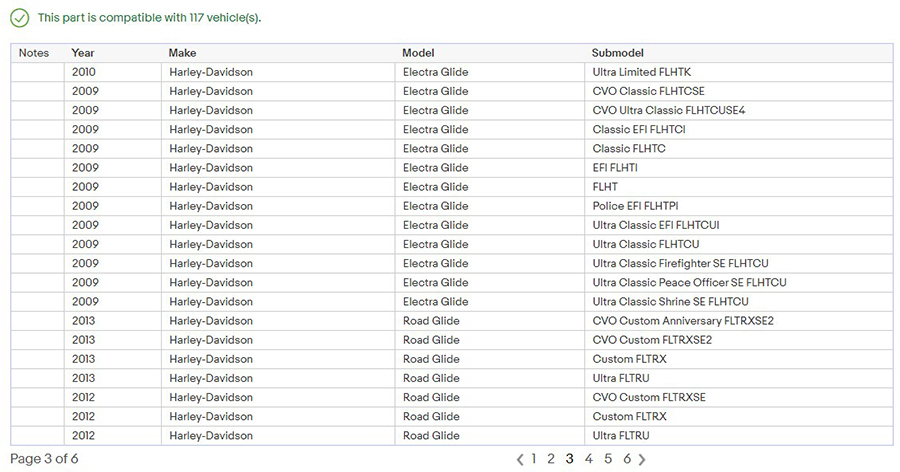

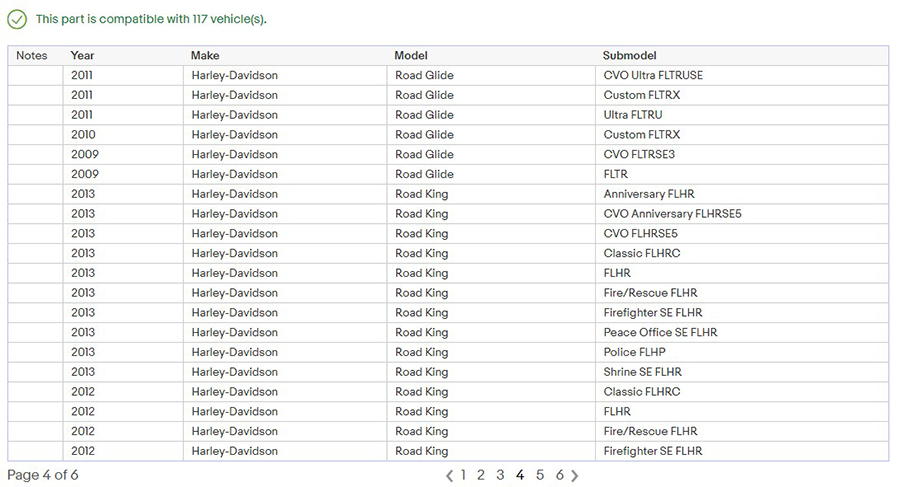

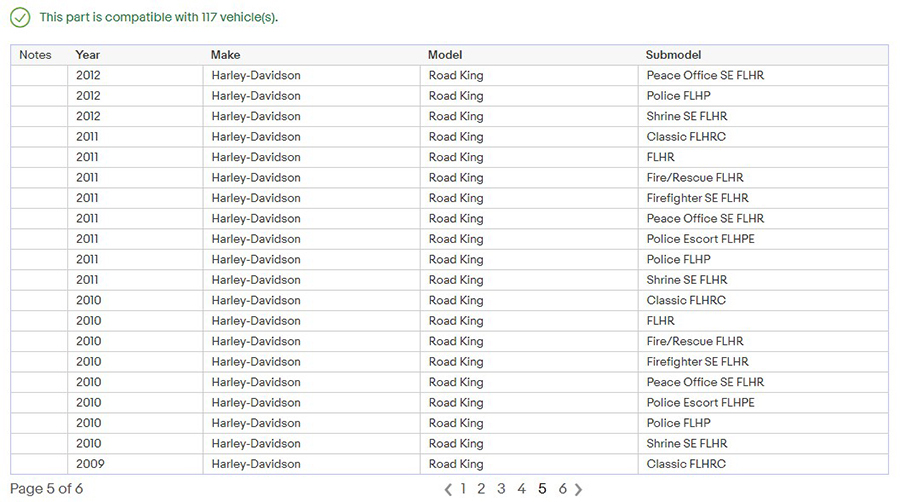

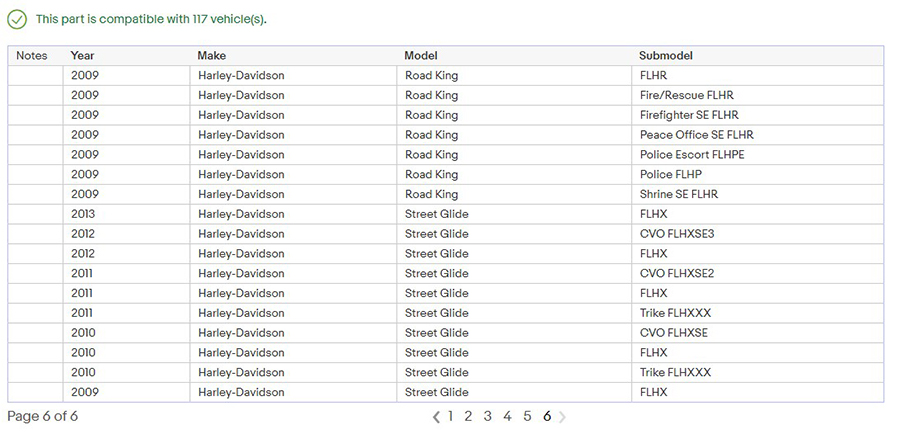

The connection bracket kit is designed to be universal and suitable for a variety of Harley-Davidson motorcycle models. Its compatibility with different models is ensured through precise engineering design and size optimization. According to the compatibility list, the connection bracket kit is suitable for 117 different sub-models of the Harley-Davidson Electra Glide, Road Glide, Road King and Street Glide series from 2009 to 2013. This wide adaptability allows users to easily complete the installation without worrying about adaptation issues, just choose the appropriate installation location and method according to their own model.

7. Lightweight design

Although it is made of high-strength steel, Black 4 Point Docking Hardware has achieved lightweight through optimized design. Each connecting bracket weighs only 1.2 kg, and the total weight of the entire connecting bracket kit does not exceed 3 kg. This lightweight design does not negatively affect the handling performance and fuel efficiency of the motorcycle, while ensuring the strength and stability of the connecting bracket. In actual use, users can hardly feel the extra weight of the connecting bracket, but can clearly feel the stability and safety improvement it brings.

8. Strict quality certification

The connecting bracket kit has passed the IATF16949:2016 quality management system certification, ensuring that every link from raw material procurement to production and processing meets international standards. During the production process, each batch of products must undergo strict quality control and testing to ensure that it meets the highest standards in terms of dimensional accuracy, load-bearing capacity and durability. In the durability test, the connecting bracket was repeatedly loaded 1,000 times, and there was no significant decline in performance, ensuring its reliability and stability in long-term use.

1. Motorcycle Modification

Black 4 Point Docking Hardware has a wide range of applications in the field of motorcycle modification. Many motorcycle enthusiasts hope to improve the performance and functionality of their vehicles through modification, and this connection bracket kit provides them with a reliable foundation. Users can easily install various modification accessories, such as luggage racks, tail boxes, rear seat cushions, etc., to enhance the long-distance travel capability and practicality of the motorcycle. For the Harley-Davidson Electra Glide series of motorcycles, after installing the connection bracket, users can install a large tail box on the bracket to carry more travel items, making long-distance travel more comfortable and convenient.

2. Police Motorcycle Equipment

In police motorcycle equipment, Black 4 Point Docking Hardware is widely used to install various special equipment. Police motorcycles usually need to install police lights, sirens, communication equipment, etc. These equipment are heavy and large in size, and require high load-bearing capacity and stability of the connection bracket. By using the connection bracket kit, police motorcycles can safely install and use various equipment to ensure stability and reliability when performing tasks. For example, the Harley-Davidson Road King Police FLHP model can utilize docking brackets to install additional communication equipment and warning lights, enhancing its functionality and safety during patrol and emergency response.

3. Firefighting Motorcycle Equipment

Black 4-Point Docking Hardware is also used to install equipment on firefighting motorcycles. Firefighting motorcycles are required to carry fire extinguishers, firefighting tools, and other emergency equipment. The weight and bulk of this equipment place higher demands on the load-bearing capacity and stability of the docking brackets. By using docking bracket kits, firefighting motorcycles can safely install various equipment, ensuring rapid response and effective mission execution in emergency situations. For example, the Harley-Davidson Road King Fire/Rescue FLHR model can utilize docking brackets to install fire extinguishers and firefighting tool kits, enhancing its functionality and safety during fire rescue operations.

4. Motorcycle Rentals

In the motorcycle rental industry, Black 4-Point Docking Hardware is widely used to modify and install equipment on rental vehicles. Rental companies can provide customers with a more comfortable and convenient riding experience by installing this docking bracket kit. For example, the Harley-Davidson Road Glide Custom FLTRX model can be equipped with a rear seat cushion and luggage rack to enhance its ability to travel long distances and attract more customers to choose rental services. At the same time, the high strength and durability of the connection bracket kit ensure the stability and reliability of the rental vehicle in frequent use, reducing maintenance costs.

5. Motorcycle maintenance and repair

In the field of motorcycle maintenance and repair, Black 4 Point Docking Hardware provides a reliable connection solution. Repairers can use the connection bracket kit to fix the motorcycle, making it more stable and safe during the repair process. For example, when performing chassis repairs or suspension system adjustments, the connection bracket can ensure that the motorcycle remains stable, making it convenient for repairers to perform various operations. Its high strength and stable connection performance provide reliable protection for maintenance work and improve maintenance efficiency and safety.

6. Motorcycle exhibitions and events

Black 4 Point Docking Hardware has also been widely used in motorcycle exhibitions and events. At the exhibition, many modification manufacturers choose the connection bracket kit as a modification part for display vehicles to show the audience its excellent effect in improving vehicle performance and appearance. In competitions, the connection bracket kit provides reliable protection for racers with its high strength and stable connection performance, helping them achieve excellent results in the competition. For example, the Harley-Davidson Street Glide FLHX model uses a connection bracket kit to install additional aerodynamic accessories during modification, which can improve its stability and performance in competitions.

1. Regular cleaning and maintenance

It is recommended to rinse the Black 4 Point Docking Hardware with clean water after use every two weeks to remove dust and dirt on the surface. For stubborn stains, use a neutral detergent and a soft cloth to wipe. Avoid using detergents containing abrasive ingredients to avoid scratching the surface of the connection bracket. For example, for heavy oil stains, you can use a small amount of motorcycle-specific detergent mixed with warm water to clean it, then rinse it with clean water and wipe it dry. Regular cleaning and maintenance like this can keep the connection bracket smooth and clean and extend its service life. In addition, when cleaning, you should pay attention to using a soft cloth and avoid using rough cleaning tools to prevent unnecessary damage to the surface of the connection bracket. This meticulous daily maintenance can not only maintain the beauty of the connection bracket, but also prevent the problem of difficulty in cleaning caused by long-term accumulation of stains.

2. Check the fasteners

Check the fasteners of the connection bracket once a month, including screws, nuts and washers. Make sure all fasteners are in a tight state. If they are loose, tighten them with a wrench or other tools in time. For example, if the torque of the screw is found to be lower than the specified 10 - 15 N·m, it should be adjusted immediately. Regular inspection of fasteners can effectively prevent the failure of the connection bracket due to looseness and ensure the stability and safety of the motorcycle during driving. During the inspection, if the fasteners are found to have signs of wear or damage, they should be replaced in time to avoid losing more than they actually are.

3. Check the anti-corrosion coating

Check the anti-corrosion coating of the connection bracket once a quarter to ensure that there is no obvious peeling or damage on its surface. If the coating is found to have signs of peeling or damage, it should be repaired in time. You can use a touch-up pen with a color similar to the original coating to touch up the paint, then gently sand it with fine sandpaper and re-polish it. For example, if the coating of the connection bracket is found to have slight peeling in some parts during the inspection, it should be repaired immediately with a touch-up pen to prevent further expansion. Regular inspection and repair of the anti-corrosion coating can effectively extend the service life of the connection bracket and maintain its good appearance and performance.

4. Check the load capacity

Check the load capacity of the connection bracket every six months to ensure that it can withstand the weight of the installed accessories. If the connecting bracket is found to be deformed or abnormally worn, it should be replaced in time. For example, if the deformation of the connecting bracket exceeds 2 mm after installing a large tail box or other heavy objects, it should be stopped and replaced with a new connecting bracket immediately. By regularly checking the load capacity, the stability and safety of the connecting bracket in long-term use can be ensured, and accidental damage caused by excessive load can be avoided.

5. Check the fit

Check the fit of the connecting bracket and the motorcycle once a year to ensure that there is no looseness or gap in the connection with the original vehicle. If looseness or gap is found in the connection, the corresponding parts should be adjusted or replaced in time. For example, if the gap between the connecting bracket and the motorcycle body is found to be more than 1 mm, it should be adjusted immediately to ensure that it fits tightly. Regularly checking the fit can effectively prevent driving safety hazards caused by loose connection parts and ensure the stability and safety of the motorcycle under various road conditions.

6. Seasonal maintenance

The maintenance method of connecting Black 4 Point Docking Hardware should also be adjusted in different seasons. For example, in winter, due to the low temperature, the metal parts of the connecting bracket may become fragile. It is recommended to clean the water stains and dirt on the surface of the connection bracket in time after use in winter to avoid cracking of metal parts due to low temperature. In addition, the air is dry in winter, so you can use some lubricants to lubricate the moving parts of the connection bracket to prevent rust. In summer, due to the high temperature, the temperature of the connection bracket will also rise accordingly. You should avoid parking the motorcycle for a long time at high temperatures to avoid burns or other damage caused by excessive surface temperature of the connection bracket. Through these meticulous seasonal maintenance measures, you can ensure that the connection bracket can maintain good condition in different seasons and extend its service life.

The motorcycle Black 4 Point Docking Hardware is an important component that connects the motorcycle steering wheel (or handlebar) and the steering gear. It is located under the motorcycle handlebar and helps the driver control the steering of the motorcycle by operating the handlebar.

The main function of the upper connecting plate is to convey the driver's steering intention. When the driver turns the handlebar, the upper connecting plate converts this action into a mechanical signal and transmits it to the steering gear, thereby controlling the front wheel steering of the motorcycle.

Depending on the design and function, the uplink plate can be divided into various types, such as hydraulic assist type, electronically controlled hydraulic assist type and electric assist type, etc. Different types of uplink plate systems may have different steering assistance functions and operating characteristics.

The design of the upper connection plate usually takes into account driving safety factors. For example, some uplink plate systems are equipped with protective devices, such as guard plates, to prevent the steering wheel (handlebar) from falling off or shifting in the event of a collision or accident, thus ensuring the safety of the driver.

If the upper coupling board fails, such as the steering is not flexible, there is abnormal noise or looseness, etc., stop the vehicle immediately for inspection. If you cannot solve it by yourself, you should contact professional motorcycle maintenance personnel for inspection and repair to ensure driving safety.

In order to maintain the good working condition of the uplink board, regular maintenance and upkeep should be carried out. This includes checking the top coupling plate for tightness, lubrication, and signs of wear or damage. If problems are found, relevant parts should be dealt with or replaced in time.

When replacing the upper connecting plate, you should select parts that match the original vehicle model and ensure they are installed correctly. During the replacement process, care should be taken not to damage other related components and professional installation procedures and specifications should be followed.

———————————————————————————————————————————————————————————————

Company Profile

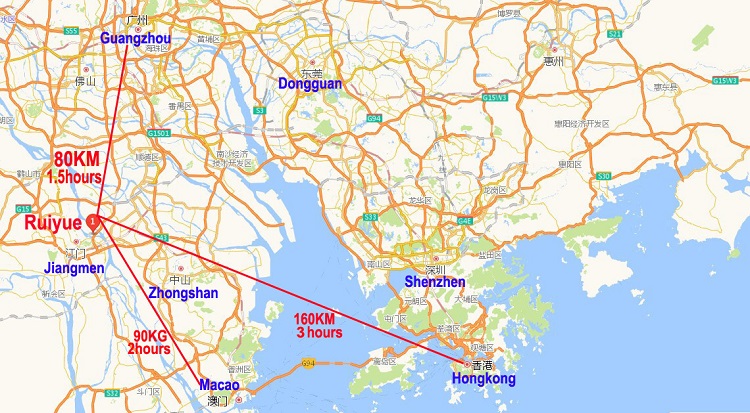

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information