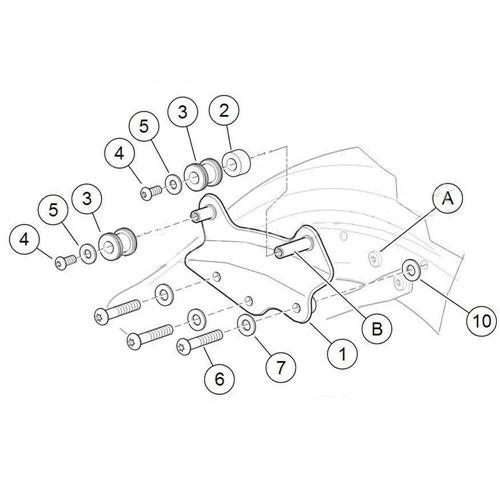

Docking Hardware Kit is an accessory installation kit for motorcycles, which usually contains the necessary hardware and tools for installing various removable motorcycle accessories. In modern motorcycle modification and customization, Docking Hardware Kit has become the tool of choice for many motorcycle enthusiasts and manufacturers due to its efficiency, convenience and versatility. It can not only quickly install and remove various motorcycle accessories, but also enhance the overall appearance and performance of the motorcycle.

Place of Origin: China

Brand Name: CRAZY OLD MAN

OEM/ODM: Availalbe

Packaging: Foam packing

Transportation: By air, by ship, by train

Application: Modified motorcycle

Payment Method: Alipay, TT, Western Union, Visa, Master Card, Credit Card, Paypal

Terms of Trade: EXW, FOB, CFR, CIF, DAP, DDP

Supply Capacity: 20000pcs in one month

Quality/Safety Certification: IATF16949:2016 quality management system

Quick Installation and Removal

Docking Hardware Kit is designed to quickly connect and disconnect accessories, reducing the time and workload of installation and removal. For example, Harley-Davidson's 4-Point Docking Hardware Kit can quickly install and remove accessories such as passenger backrests, luggage racks and travel bags.

Versatility

The kit is suitable for a variety of motorcycle accessories, including but not limited to backrests, luggage racks, travel bags, etc. This versatility allows users to easily replace and add accessories according to different needs and scenarios.

High-quality materials

Docking Hardware Kit is usually made of high-quality materials such as stainless steel and aluminum alloy, ensuring its durability and reliability. For example, Harvard Chrome's 4-Point Docking Hardware Kit is made of high-quality steel with a chrome finish and comes with a one-year warranty.

Easy to Install

Most Docking Hardware Kits are designed to be easy to install, without the need for specialized tools or skills. For example, HOGWORKZ's Docking Hardware Kit includes all the hardware needed for installation, ensuring a quick and painless installation process.

Customization

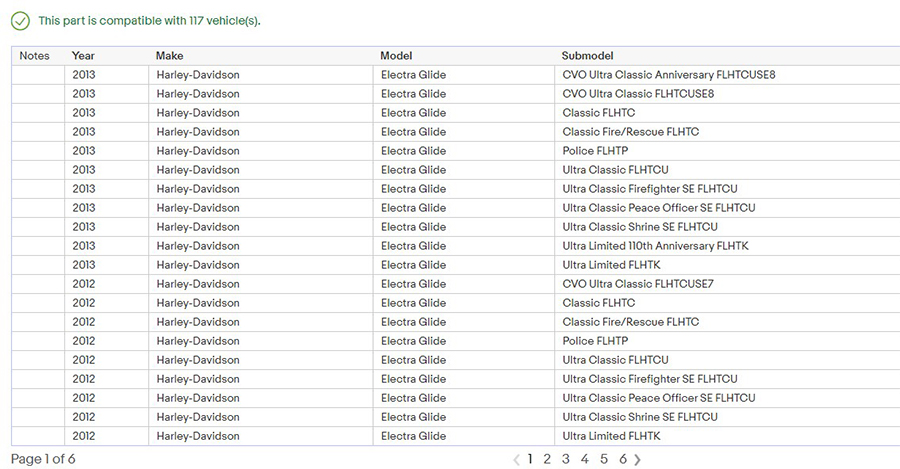

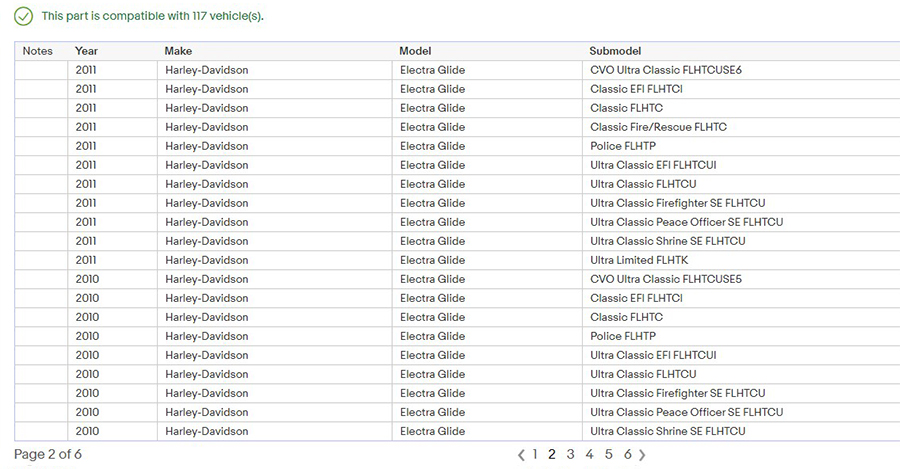

Some Docking Hardware Kits offer customization services and can be customized to the user's specific needs and motorcycle model. For example, Kraus Moto's Pro-4 Docking Hardware Kit is designed for Harley-Davidson and other brands of motorcycles and provides mounting points that are compatible with original accessories.

Motorcycle modification

In motorcycle modification, Docking Hardware Kit is used to install a variety of customized accessories such as backrests, luggage racks, and travel bags. This kit not only improves the functionality of the motorcycle, but also enhances its appearance and personalization.

Commercial use

In motorcycle rental and travel businesses, Docking Hardware Kit allows for quick replacement and installation of accessories to meet the needs of different customers. For example, rental companies can quickly install or remove luggage racks and travel bags according to the needs of customers' itineraries.

DIY Projects

For motorcycle enthusiasts who like DIY, Docking Hardware Kit provides a convenient accessory installation solution, allowing them to easily modify at home.

Industrial Uses

In industrial environments, Docking Hardware Kit can be used to quickly install and remove various equipment and tools to improve work efficiency.

Floating Dock Construction

In floating dock construction, Docking Hardware Kit is used to install and fix various floating dock components to ensure the stability and safety of the dock.

Daily Cleaning

Daily cleaning of Docking Hardware Kit is relatively simple. Use a damp cloth to wipe the surface to remove dust and stains. For difficult-to-clean areas, a soft brush can be used for local cleaning.

Regular Inspection

Regularly check the connection of the mounting points and accessories to ensure that there is no looseness or damage. If problems are found, they should be repaired or replaced in time to ensure the safety and reliability of the accessories.

Protective Measures

During cleaning and maintenance, avoid scratching the surface of the mounting kit with hard objects to avoid damaging its appearance. At the same time, prolonged exposure to humid or corrosive environments should be avoided to prevent rust and corrosion.

———————————————————————————————————————————————————————————————

Company Profile

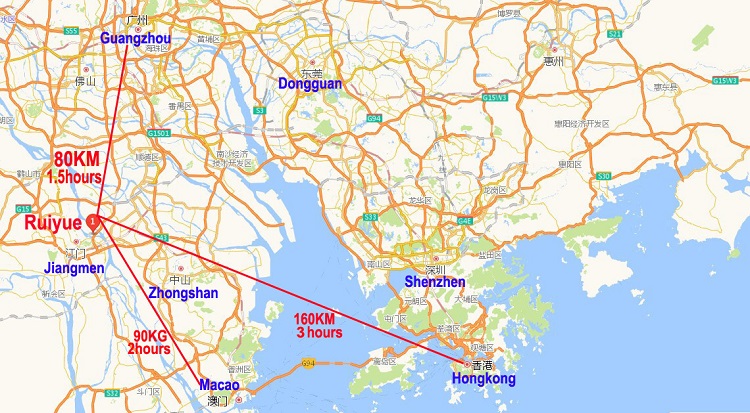

Jiangmen Ruiyue Industry Co., Ltd. was founded in Dec, 2004, located in Jiangmen City, Guangdong Province where is one of the Chinese three biggest motorcycle production base. The factory covers an area of 24000 square meters and building area of 20000 square meters, more than 80 million fixed assets. Specializing in modified motorcycle exhaust muffler, fuel tank, fender and carbon fiber parts with design, development, production and marketing.

———————————————————————————————————————————————————————————————

Technical Advantages

Ruiyue has more than 200 employees, including 50 R&D, design and professional technicians. Ruiyue have implemented the IATF16949:2016 quality management system.

Ruiyue has two differentiation fuel tank production lines with a monthly production capacity of more than 20000pcs tanks, also have two exhaust (muffler) production lines with a monthly production capacity of more than 20000sets exhausts. In order to ensure the reliability of product quality, Ruiyue has set up a laboratory equipped with a number of special testing equipment.

In recent years, we also introduced more than 100 sets of advanced professional equipment such as full-automatic CNC pipe bender machine, laser welding equipment, full-automatic rounding machine, internal high-pressure expansion equipment, and automatic networking making machine. Our factory is still continuously introducing advanced and efficient automation and intelligent equipment, and has established a product research and development center to continuously meet the higher requirements of more customers.

———————————————————————————————————————————————————————————————

Honor Certificate

Ruiyue provide high quality and stable supporting services with more than tens main motorcycle manufacturers such as BENDA ,COLOVE, JIANYA, KAYO MOTO. We also have a long-term partner of many international well-known motorcycle modification brands. Ruiyue’s products are best-selling in Europe, America, Japan, Korea, Southeast Asia and domestic markets. We have won the domestic and foreign customers trust and praise by design professional fashion style and exquisite quality.

———————————————————————————————————————————————————————————————

Exhibition Information